HOOFCOUNT

INVEST IN A PROVEN HOOFCARE SYSTEM –

Automation for Healthy Cows!

Automation for Healthy Cows!

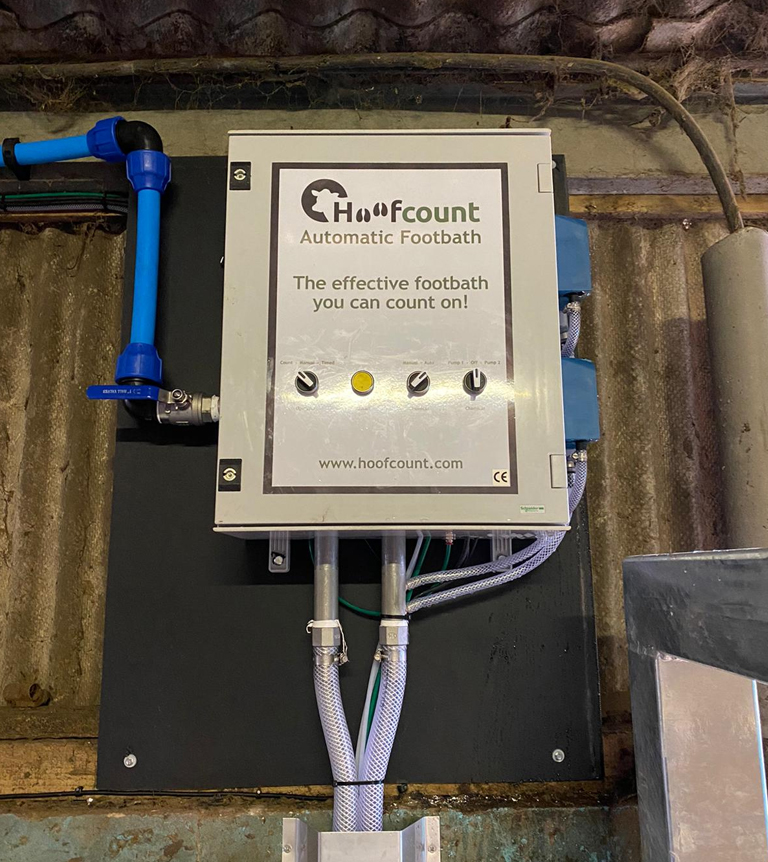

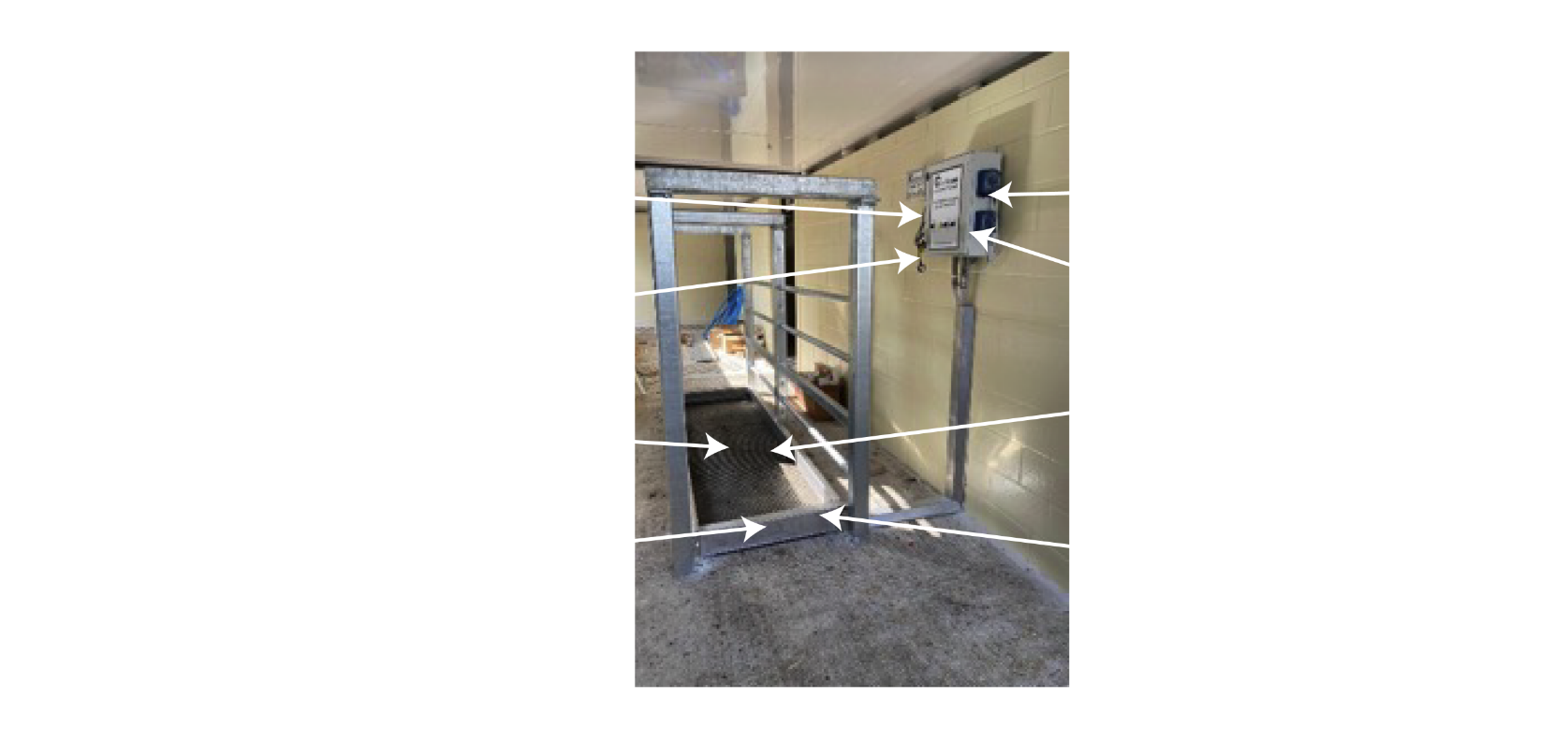

Hoofcount is a unique hoof care system to help milk and meat producers reduce lameness issues on farm, improve animal wellbeing, hoof health and overall animal performance. It is an automated footbath that comes in a variety of sizes, from 2.5m to 3.6m long. Has two separate chemical pumps, empties, cleans and re-fills in 3 minutes after the required number of cow passes, is built of the strongest materials to lengthen its working life and even contains a rubber floor to optimise cow comfort as they pass through the footbath.

It counts the cows as they pass, has two separate chemical pumps, empties, cleans and re-fills in 3 minutes after the required number of cow passes, is built of the strongest materials to lengthen its working life and even contains a rubber floor to optimise cow comfort as they pass through the footbath.

Stainless steel bath (2.5m, 3m or 3.6m long), with 8 folds for additional strength. It comes complete with full width opening door for rapid emptying of footbath solution. It has a double pump system to allow the bath to have two individual chemicals added, at varying concentrations.

The system can be set to work in various ways:- Sensor to count the cows as they pass.

- Timer

- Manually.

The bath has a unique ‘spray wave system’ to rapidly flush and clean the foot bath after say 100-200 cow passes. It can fully empty, flush out and re-fill the bath in 3 minutes.

The chemical concentration can be set at the desired percentage (1-5%), along with the days you wish it to be added to the bath.

There are ‘two chemical pumps’, which allows two different chemicals to be used and it can even be set on different days (the ultimate in hoofcare flexibility and total-control).

KEY FEATURES

- Low running costs.

- Simple to use.

- Screen/Smart Phone connectivity.

- Simply set the Hoofcount on automatic and this then works as part of your hoofcare routine.

- By setting the Hoofcount to empty, flush and refill after 150 cows, this prevents the footbath solution getting unnecessarily contaminated with faecal material.

- Fully stainless-steel system for reliability.

- Can take your choice of liquid chemicals.

Play Video

9 STEP EMPTYING, CLEANING & FILLING PROCESS

Hoofcount In Brief

VARIETY OF OPTIONS

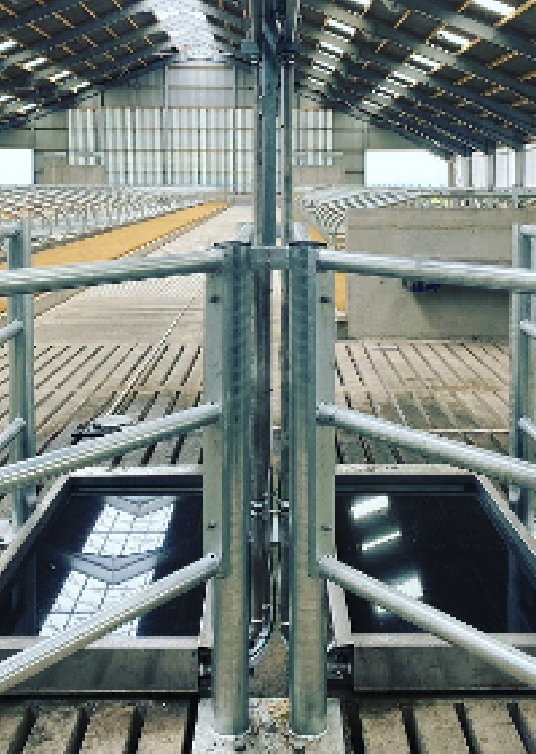

STANDARD FOOTBATH

2.5-3m long and 800mm (internal) width. Facilitates ‘2 dips per hoof’. Ideal for smaller herds with less than 200 cows, also Robotic milking farms.

The footbath holds up to 240L of solution at 100mm deep. This footbath can be operated using the cow counter, a timer or manually. The operator can decide the chemical, concentration and how often to footbath. A general rule of thumb can be daily, used at very low chemical concentration (~1.5%). The ‘spraywave spraybar’ ensures the bath is washed out fully from top to bottom and will wash out any excess mud or faecal material during the washing process.

The iCam touch screen control box is new optional extra and is ideal for farms with more than one footbath and this ensures all footbaths on farm are working in the exact same way. In addition, vets and hoof trimmers can input lameness data to help deal with lameness in the best possible way.

2 Dips Per Hoof

3 Dips Per Hoof

EXCEL FOOTBATH

3.7m long and 600mm (internal) wide. It allows 3 dips per hoof. Ideal for larger units, above 200 cows (eg Rotary or Large Herringbone farms). Has strong stainless-steel side sheets to prevent cows stepping on the sides of the bath. The bath is also narrower to optimise chemical use.

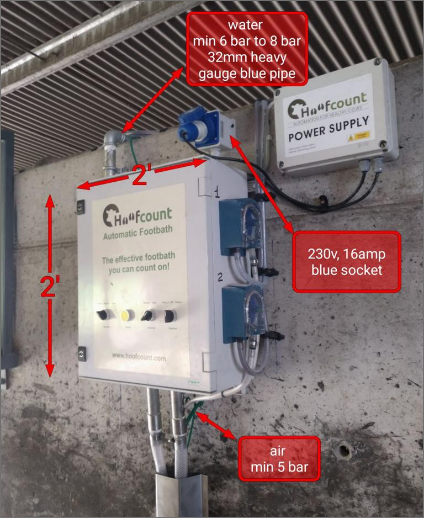

CONTROL BOX

- Allows for manual, timed and cow count sensors to operate the footbath.

- Easy to use.

- Two independent pumps for two separate chemicals.

- Allows for various chemical concentrations from 1-5%.

- Now with connectivity for remote operation.

Play Video

SPRAYWAVE

- Once the full width door opens at the front of the Footbath to release the

contents of the bath, the Spraywave sprays water through high pressure jets

from the rear of the bath. - It uniquely oscillates up and down to facilitate a rapid and thorough

cleaning of the bath before re-filling.

PLANNED HOOFCARE APPROACH

- Identify lame cows early and deal with each case promptly.

- Efficient foot trimming routine.

- Routine foot bathing.

- Good roadways.

- Good yard design with good clean flooring.

- Mobility score cows regularly.

ANNUAL SERVICE

- Change chemical tubes

- Replace rubber door seals

- Top-up oil in the control box

- Re-calibrate the pump

- Clean the cow counter.

- Check the chemical supply.

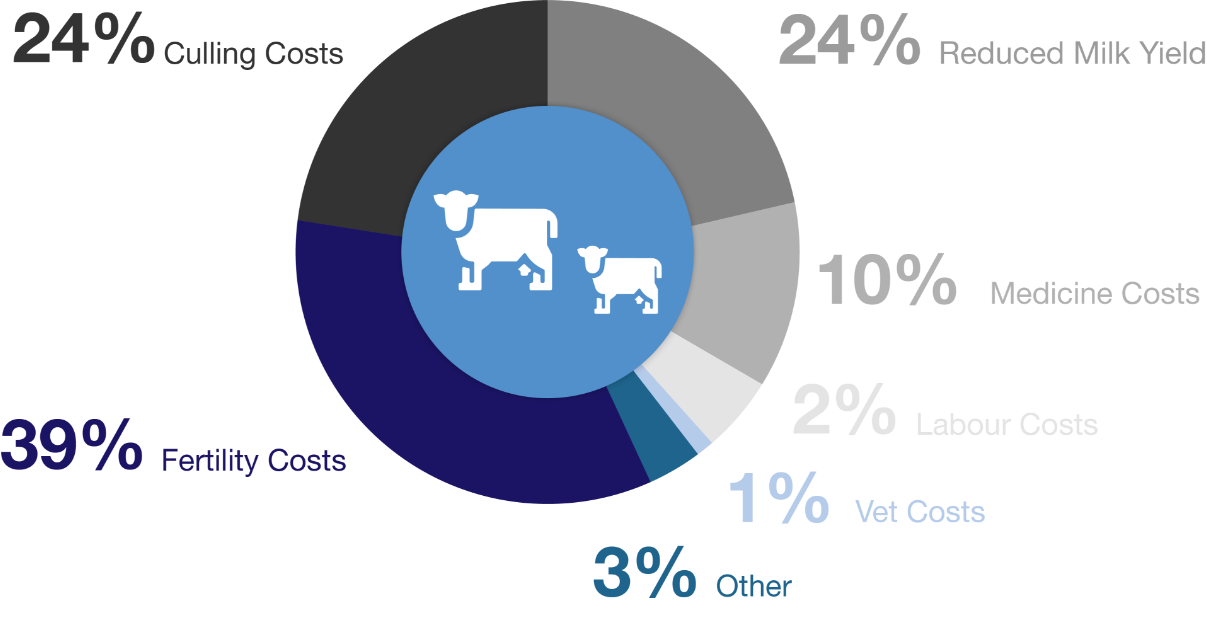

ANNUAL COST OF

LAMENESS FOR A DAIRY

LAMENESS COST

Source Eoin Ryan MVB and Luke O’Grady BVMS MRCVS of UCD in 2004, when they studied the Economics of Infectious and Production Diseases in Irish Dairy Herds

COST OF LAMENESS

- Reduces milk and meat yield’s due to reduced grazing and eating times.

- Reduces fertility performance.

- Poorer cow longevity on the farm.

- Increased hoof trimming costs.

- Extra unnecessary labour – it takes 20 times more time input to handle a sick cow vs a health cow.

€250 - €300

Case of lameness costs

- 20-35% of cows suffer some degree of lameness.

- 80% of lameness cases are in the hind limbs and 80% of these cases are in the outer claw.

- Clinical lameness cases are estimated to reduce milk yield by 350kg per lactation.

- A case of clinical lameness is estimated to cost €250.

- Discarded milk.

- Veterinary bills and antibiotics.

- Additional labour to handle the lame cows.

- Reduced fertility: cows unwilling to stand in heat, jump on other cows, can have delayed cycling after calving.

- Increased risk of further lameness.

- Increased risk of secondary disease.

- Cows lose condition due to unwillingness to stand to feed (typically 2 hours less eating time per day).

- Increased risk of culling.

Its estimated that lameness costs a typical 100 cow herd in Ireland €5,500/year. Hoofcount can be used as part of overall effective lameness management routine to improve hoof health and animal performance.

THE SOURCE

Sources of lameness comes from bacteria like digital dermatitis (mortellaro), environment (ie. roadways, yard surfaces – white line and sole ulcers) and the diet (ie. laminitis).

Once you identify the cause of lameness issues on farm, a program of control can be implemented to prevent further re-occurrence, including routine hoof-trimming, footbathing, improving hygiene in sheds, managing road surfaces and balancing the diet for optimum hoof health.

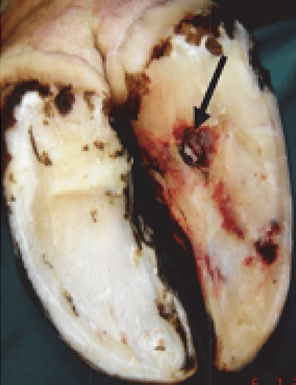

Mortellaro

Soleulcer

White-Line

Locomotion Score cows to assess level of lameness issues in your herd

It is good practice to locomotion score your cows monthly to assess how at ease cows are at walking. This is a graded system from 1-5 (1 being normal; 3 being moderately lame and 5 being severely lame). In addition, routine hoof trimming is highly recommended.

..if a cow is off form, it sends me an alert to say she is not eating properly, the system picks her up before you pick her up… the Drafting System is cutting 20 minutes off each milking and the cows got used to the Drafting System in one day.

Johnny Flanagan, Horse & Jockey, Thurles,

Tipperary 145 spring calving cows.

Tipperary 145 spring calving cows.

Click Here

When I am away from the herd, it is great to know that when a cow is sick, I will know before the person in the parlour….I bought SenseHub to make life easier for myself… I don’t have to spend early mornings and late evenings checking if tail paint gone and also not having to tail paint saves a lot of time.

Gearoid Ryan, Two-Mile-Borris,

Tipperary.

Tipperary.

Click Here

Prior to the SenseHub collars the only form of heat detection was tail paint…the first benefit with going with the collars was we went 100% AI, which allows maximum flexibility year in and year out to implement the breeding system we want. The second benefit was we reduced our breeding season from 12 weeks to 10 weeks and submitted 97% in 3 weeks and had a conception rate of 73%... the Drafting System is critical as all elements works under the one brain… it automatically drafts out the animals

Enda Walsh, Oranmore,

Galway

Galway

Click Here

Fits into the drafting gate lovely…. the cows got a strong dose for week to 10 days and within 3-5 you could see an improvement… it took cases from 25% mortellaro to 3%.....it works super, I could not recommend it enough and the fitting and service was super… money well spent

Noel Keane, Kilbaha,

Co. Clare (200 cows)

Co. Clare (200 cows)

Click Here

I had the old Heatime system … and upgraded 18 months ago to SenseHub and it’s a good upgrade. It worked very good this year. Any cows bulling, they were drafted out when every they needed to be taken out. I’d recommend it to anyone. Especially for anyone working on their own. It’s a one-man system here. It’s very handy for AI and drafting cows. It works with a drafting gate… I do my own AI… the cows are there ready to be done

Bernard O’Gorman, Taghmon,

Co. Wexford (120 cows)

Co. Wexford (120 cows)

Click Here

Pre-breeding alone is very useful, you can check 3 weeks pre-breeding and do your intervention with cows not cycling, just off the report on the SenseHub system…very happy with the Drafting System, it hasn’t missed a cow yet… anything bulling gets drafted

David Melody, Farm Manager,

Beechgrove Farm, Clara, Kilkenny

Beechgrove Farm, Clara, Kilkenny

Click Here

I find it fantastic, it’s easy to use, quick to clean out, lame cows are drafted through morning and evening. There is no problem with cows walking through it. I had the plastic footbaths and it was hard to get them to walk through it… It’s absolutely fantastic and I have the choice of detergents I can use in it as well

Michael Power, Kilmanagh,

Co. Kilkenny (200 cows)

Co. Kilkenny (200 cows)

Click Here